Moulds

At Cornelius Electronics, we understand that the quality of your vacuum formed products begins with the mould. That’s why we offer comprehensive mould making solutions to ensure the best possible results for your projects. Our expertise in mould design and fabrication complements our vacuum forming services, providing you with a one-stop solution for your manufacturing needs[1].

Our Mould Making Capabilities:

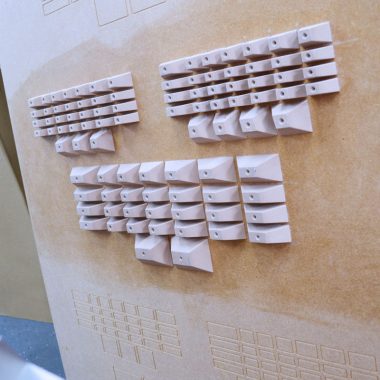

CNC Machined Moulds:

Using our advanced CNC technology, we can create precise, complex moulds from a variety of materials. This method is ideal for high-volume production and ensures consistency across large runs.

3D Printed Moulds:

For prototyping or low-volume production, we offer 3D printed moulds. This cost-effective solution allows for rapid iteration and testing of designs before committing to full production.

Cast Aluminium Moulds:

For projects requiring durability and heat resistance, we can produce cast aluminium moulds. These are excellent for long production runs and materials that require higher forming temperatures.

Epoxy Tooling:

We offer epoxy tooling solutions for projects that require a balance between durability and cost-effectiveness. These moulds are suitable for medium production runs and can be produced quickly.

Wood and MDF Moulds:

For certain applications or prototype runs, we can create moulds from wood or MDF. These are cost-effective for low-volume production or concept validation.

Why Choose Cornelius Electronics for Mould Making?

Integrated Services: By handling both mould making and vacuum forming in-house, we ensure seamless production and consistent quality.

Experience: With over three decades in the industry, we have the expertise to tackle complex mould-making challenges[1].

Advanced Technology: Our investment in cutting-edge CNC and 3D printing technology allows us to produce high-quality moulds efficiently.

Quality Assurance: Our ISO 9001 certification demonstrates our commitment to maintaining rigorous quality standards throughout the mould-making process[1].

Customisation: We tailor our mould-making solutions to your specific needs, ensuring you get the best possible outcome for your project.

Support: Our team provides ongoing support, from initial design consultation through to production and beyond.

Forming

an air tight

partnership

Mould making

questions & answers...

Yes, all moulds are designed and manufactured on-site for better control and faster turnaround.

Moulds can be made from wood, resin, or metal, depending on the project needs.

Lead times vary, but in-house production speeds up the process.

Yes, moulds can be adapted or repaired as needed.

Expert guidance is provided to ensure moulds are optimised for vacuum forming.

Where we supply

- Aerospace Industry

- Medical Industry

- Maritime Industry

- Agricultural Industry

- Telecommunications

- Electronics & Gaming

- Automotive Industry

- Machine Building

- Retail and Display

- Construction Industry

- Renewables Energy

- Product Prototype