Vacuum forming in the UK is undergoing significant transformation, fuelled by technological advances and a focus on sustainability.

Automation and Digital Technologies

The industry is embracing automation, robotics, and digital simulation tools to improve precision, productivity, and efficiency. These innovations help reduce lead times and enable rapid prototyping for faster product development.

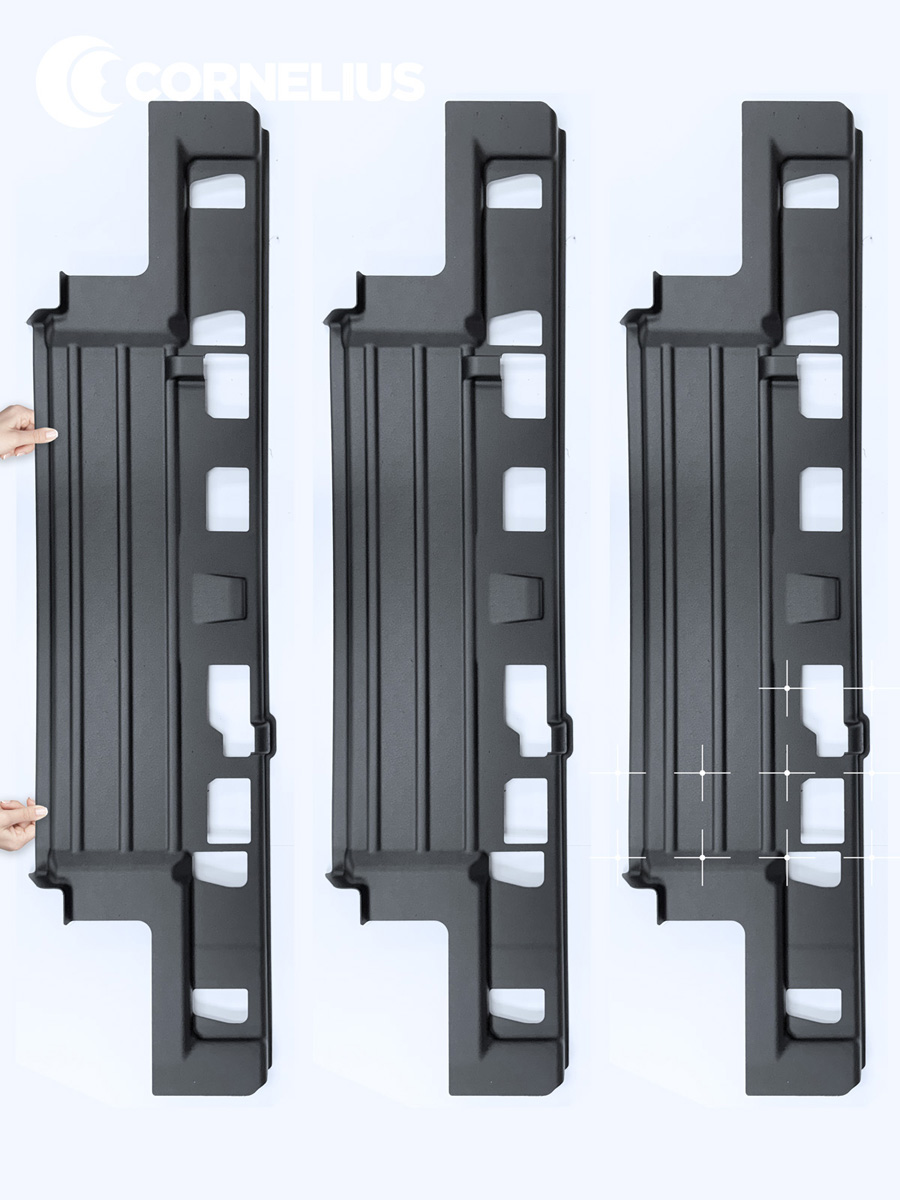

Material Innovation

A wider selection of high-performance plastics, such as ABS, polycarbonate, and polypropylene, allows for greater customisation and enhanced product durability, appearance, and performance.

Sustainability

Sustainable materials and processes are a major focus, with manufacturers adopting recyclable plastics and energy-efficient production methods to minimise environmental impact.

On-Demand and Custom Manufacturing

Greater automation and digital manufacturing make it possible to offer more personalised, on-demand production, meeting the rising demand for customised products without significant cost increases.

Cornelius’s Commitment

Cornelius Vacuum Forming is committed to investing in cutting-edge technologies and sustainable practices, delivering efficient, innovative, and environmentally responsible solutions for its clients.