Vacuum Forming

At Cornelius Electronics, we pride ourselves on delivering top-tier vacuum and thermo forming services to meet the diverse needs of industries across the UK and beyond. With over three decades of experience in vacuum thermoformed mouldings, we have established ourselves as a leader in the field.

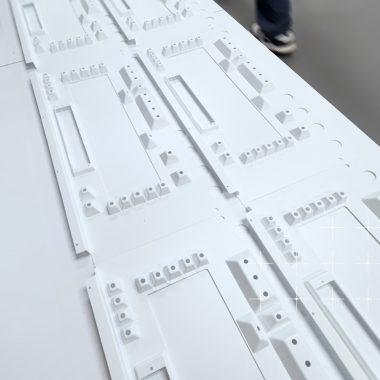

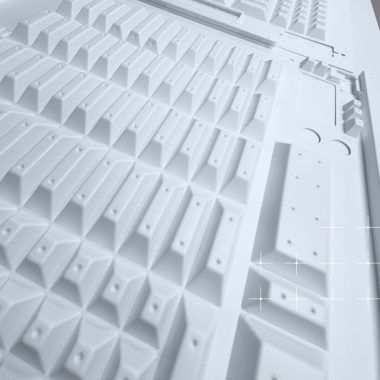

Our state-of-the-art 5,000 square feet forming facilities house an impressive array of large and mid-format vac-form machines, capable of handling forming areas ranging from 800mm to 2000mm. This extensive capacity allows us to tackle projects of various scales, from small components to large industrial parts.

Our vacuum forming process involves heating a sheet of plastic until it becomes pliable, then using vacuum pressure to shape it over a mould. This versatile technique allows for the creation of complex shapes and designs, making it ideal for a wide range of applications. Whether you need prototypes, short production runs, or high-volume manufacturing, our vacuum forming services can accommodate your requirements.

Thermo forming, a closely related process, involves heating plastic sheets to a pliable forming temperature, shaping them to a specific mould using pressure, and trimming them to create usable products. Our expert team excels in both vacuum and thermo forming techniques, ensuring that we can provide the most suitable solution for your project.

Our dedicated team of operators is skilled in handling materials ranging from 1mm to 10mm in thickness, allowing us to cater to a broad spectrum of product specifications.

By choosing Cornelius Electronics for your vacuum and thermo forming needs, you benefit from:

- Precision and quality: Our advanced machinery and experienced team ensure consistently high-quality results.

- Flexibility: We can accommodate both small and large production runs.

- Cost-effectiveness: Vacuum and thermo forming often provide a more economical solution compared to other manufacturing methods.

- Rapid turnaround: Our efficient processes allow for quick production times.

- Design support: Our in-house design team can assist with product development and optimisation.

Vac Form

solutions

for industry

Popular vacuum

forming questions...

Vacuum forming is popular in automotive, retail, packaging, medical, and industrial sectors.

Yes, services are available for single prototypes, small batches, and large-scale production.

We can create components using 1mm to 10mm thick, on a forming area of 800mm to 2000mm.

Yes, options include trimming, cutting, polishing, and full assembly.

Strict quality checks and experienced staff ensure every part meets specifications.

Where we supply

- Aerospace Industry

- Medical Industry

- Maritime Industry

- Agricultural Industry

- Telecommunications

- Electronics & Gaming

- Automotive Industry

- Machine Building

- Retail and Display

- Construction Industry

- Renewables Energy

- Product Prototype